From style and machinery import to commissioning and teaching, we help you at each individual step on the journey. Now we have served builders, builders, and architects convey their visions to lifestyle over the years.

Horizontal AAC Block Machines :- Molds that go horizontally down the output line are a function of horizontal machines. They may be usually employed in high-quantity manufacturing environments and supply flexibility in running distinctive block dimensions.

Precise processing improves the consistency and high-quality of your AAC blocks, lessening material squander and strengthening output efficiency.

The cutting part features significant-precision chopping products that slices the pre-cured blocks into wished-for measurements and designs with minimal wastage.

Autoclave :- The autoclave is often a substantial-tension steam chamber that cures the Slash blocks below managed ailments. This method improves the power and toughness of the AAC blocks.

The packing portion includes automatic techniques for stacking, packing, and securing concluded AAC blocks for transport.

Integrates a sturdy production administration system that permits serious-time monitoring and control of the manufacturing system. This system makes certain operational efficiency, consistency in product or service high quality, and the opportunity to adapt to different production needs.

Also known as brick-making machines, our AAC Block Making Machines are produced with remarkable quality specifications to guarantee longevity and performance. Dedicated to excellence, we offer these high-efficiency machines at competitive prices, making them an excellent choice for firms in the development market.

State-of-the-art checking methods be certain the highest excellent expectations are preserved all over the creation approach. Tough machinery with minimal maintenance desires reduces downtime and guarantees ongoing Procedure. Elements Supplied by Brickwell

Brickwell presents automated units with the fabrication and circulation of metal mesh, which serves as reinforcement for AAC panels.

Our AAC division stays focused on supporting top quality construction through Sophisticated and effective manufacturing programs throughout India.

With around 20 years of expertise, we provide one-prevent company answers that maximize production efficiency and capacity whilst making certain long-expression trustworthiness.

Conveyor Programs: These units transport raw supplies and completed items all over the generation line, ensuring effectiveness and lessening handbook labor.

They deal with every action from the production course of action, from packaging to mixing. Large manufacturing amenities that require superior output while preserving continual top quality are the right fit for these gear.

Slicing Machine:-chopping machines slice it into personal blocks. These machines can accomplish both equally vertical and horizontal cuts.

The pouring program is suitable for precise and controlled filling of molds Together with the AAC slurry, even though the pre-curing course of action guarantees the combination achieves the ideal regularity and power right before further more processing. This portion guarantees dimensional precision and enhances the quality of the ultimate merchandise.

Moulds: Moulds condition the slurry into blocks. They are often personalized to make different measurements and designs of AAC blocks.

An AAC block making click here machine is usually a specialised piece of kit built to create autoclaved aerated concrete blocks. These machines streamline the manufacturing approach by automating several phases like mixing, pouring, cutting, and curing. The result is a superior-good quality product that meets the demands of modern construction.

Vertical AAC Block Machines :- Vertical molds that vacation through each individual generation move are employed by vertical machines. They can be absolutely automated for top-capacity output and optimize Place efficiency.

Helpful undertaking administration and preparing Responsible gear offer and logistics Supervised set up for precision and high quality With a strong research and advancement workforce, Sophisticated creation devices, along with a properly-recognized source chain, Brickwell assures extensive and timely alternatives for its consumers.

Offering you the most effective number of mini aac block manufacturing plant, very low investment startup aac plant, aac updragable alc block plant, small aac blocks plant, totally automatic aac plant and semi computerized aac block making machine with effective & timely shipping.

We provide a comprehensive just after-sales company framework to ensure exceptional plant effectiveness and effectiveness. Services incorporate:

Considering that 2010 Brickwell has served Builders, Builders, and Architects, remodel their desires into wonderful constructions that enhance and improve any environment. Brickwell is within the forefront of introducing innovating present day development items and answers to enhance efficiency and profitability.

Plant planning and design and style Manufacturing and installation Commissioning and personnel training Uncooked content configuration and tests By specializing in components like factory infrastructure, local current market trends, and environmental ailments, Brickwell ensures a seamless setup process that aligns with certain complex needs.

Brickwell empowers firms by offering cutting-edge AAC plant options that satisfy international criteria, paving the way to get a greener plus much more economical long term in constructing elements production.

This guarantees compliance with task requirements and facilitates economical use in design jobs.

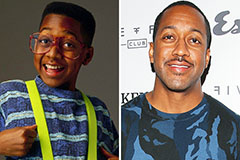

Jaleel White Then & Now!

Jaleel White Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now!